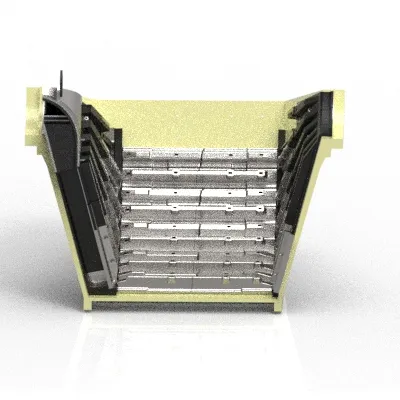

The SAG composite liner is a crucial component in SAG mills, with the following details:

- Materials and Structure

- Materials: Usually combines metal materials such as Hardox 500 steel inserts and wear-resistant rubber compounds. The metal parts provide high strength and impact resistance, while the rubber parts offer good shock absorption and noise reduction properties.

- Structure: It consists of metal components and rubber components that are precisely combined. The metal inserts are strategically placed within the rubber matrix to form a unified structure, which can effectively withstand the impact and wear of materials and grinding media in the SAG mill.

- Functions and Advantages

- Excellent Impact Resistance: The metal inserts in the composite liner can withstand the strong impact of ores and grinding media, ensuring the liner's integrity and stability under high-impact conditions.

- Good Shock Absorption and Noise Reduction: The rubber part of the composite liner has excellent elastic properties, which can absorb the vibration and impact energy generated during the SAG mill's operation, reducing noise and improving the working environment.

- High Wear Resistance: The combination of metal and rubber materials endows the composite liner with high wear resistance, prolonging its service life and reducing the frequency of liner replacement compared to traditional single-material liners.

- Effective Energy Saving: The rubber part of the composite liner has a lower density than metal, reducing the overall weight of the liner and the SAG mill, thereby reducing energy consumption and improving the mill's energy efficiency.

- Optimal Grinding Performance: The 合理的结构 design of the composite liner can guide the movement of materials and grinding media more effectively, improving the lifting and stirring effects, and thus enhancing the overall grinding efficiency of the SAG mill.

- Good Corrosion Resistance: The wear-resistant rubber compound in the composite liner has certain corrosion resistance, which can protect the liner from the erosion of slurry and chemical substances in the grinding process, prolonging the liner's service life.

- Applications

- Mining Industry: It is widely used in large SAG mills in mines for grinding various ores such as copper, gold, and iron, improving grinding efficiency and reducing equipment wear.

- Metallurgical Industry: Applied in the pretreatment of metal ores in metallurgical plants to provide high-quality raw materials for subsequent smelting.