The SAG mill metal liner is of great significance in the grinding process of the SAG mill. The details are as follows:

- Materials

- Cr-Mo Alloy Steel: The main material is often Cr-Mo alloy steel, which contains specific amounts of chromium and molybdenum. For example, medium Cr-Mo liner plates have a chromium content of 4 - 6% and a carbon content of 0.4 - 0.8%, while low Cr-Mo liner plates have a chromium content of 1.2 - 2.5% and a carbon content of 0.3 - 0.6%.

- Other Elements: Besides Cr and Mo, other elements may be added to improve performance, such as increasing carbide content in medium carbon alloyed steel to enhance heat resistance and wear resistance.

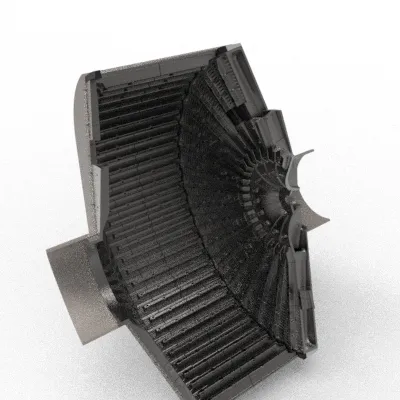

- Structure

- Shell Plates: These cover the inner wall of the SAG mill cylinder, directly bearing the impact and friction of materials and grinding media.

- Lifter Bars: Installed on the inner wall of the cylinder, they lift and stir materials and grinding media, improving grinding efficiency and ensuring uniform mixing.

- Functions and Advantages

- Superior Wear Resistance: The metal liner, with its high-hardness alloy materials, can resist the abrasion of materials and grinding media, thus prolonging the service life of the SAG mill.

- Excellent Impact Resistance: It can withstand the strong impact of materials and grinding media during the SAG mill's operation, ensuring the integrity and stability of the liner.

- High Strength and Toughness: The Cr-Mo alloy steel liner has a good combination of strength and toughness, enabling it to handle high-intensity grinding tasks without easy deformation or breakage.

- Good Heat Resistance: It can endure the heat generated during the grinding process, maintaining stable performance in high-temperature environments.

- Optimal Grinding Performance: By properly designing the structure of the liner, especially the lifter bars, it can improve the lifting and stirring effects of materials and grinding media, thereby enhancing the overall grinding efficiency of the SAG mill.

- Production Process

- Casting Process: It usually involves steps like casting process design, model making, resin mold modeling, molten steel melting, molding, solidification and thermal insulation stress relief, cleaning and polishing.

- Heat Treatment: Normalizing heat treatment and shot blasting may be carried out to improve the material's microstructure and mechanical properties, enhancing hardness, wear resistance and toughness.

- Applications

- Mining Industry: Widely used in the grinding of various ores such as iron, copper, molybdenum, gold and uranium in mines.

- Metallurgical Industry: Applied in the pretreatment process of metal ores in metallurgical plants to prepare high-quality raw materials for subsequent smelting.