The trommel screen at the discharge end of the mill is of great significance in the material processing process. The following are the details:

- Structure and Working Principle

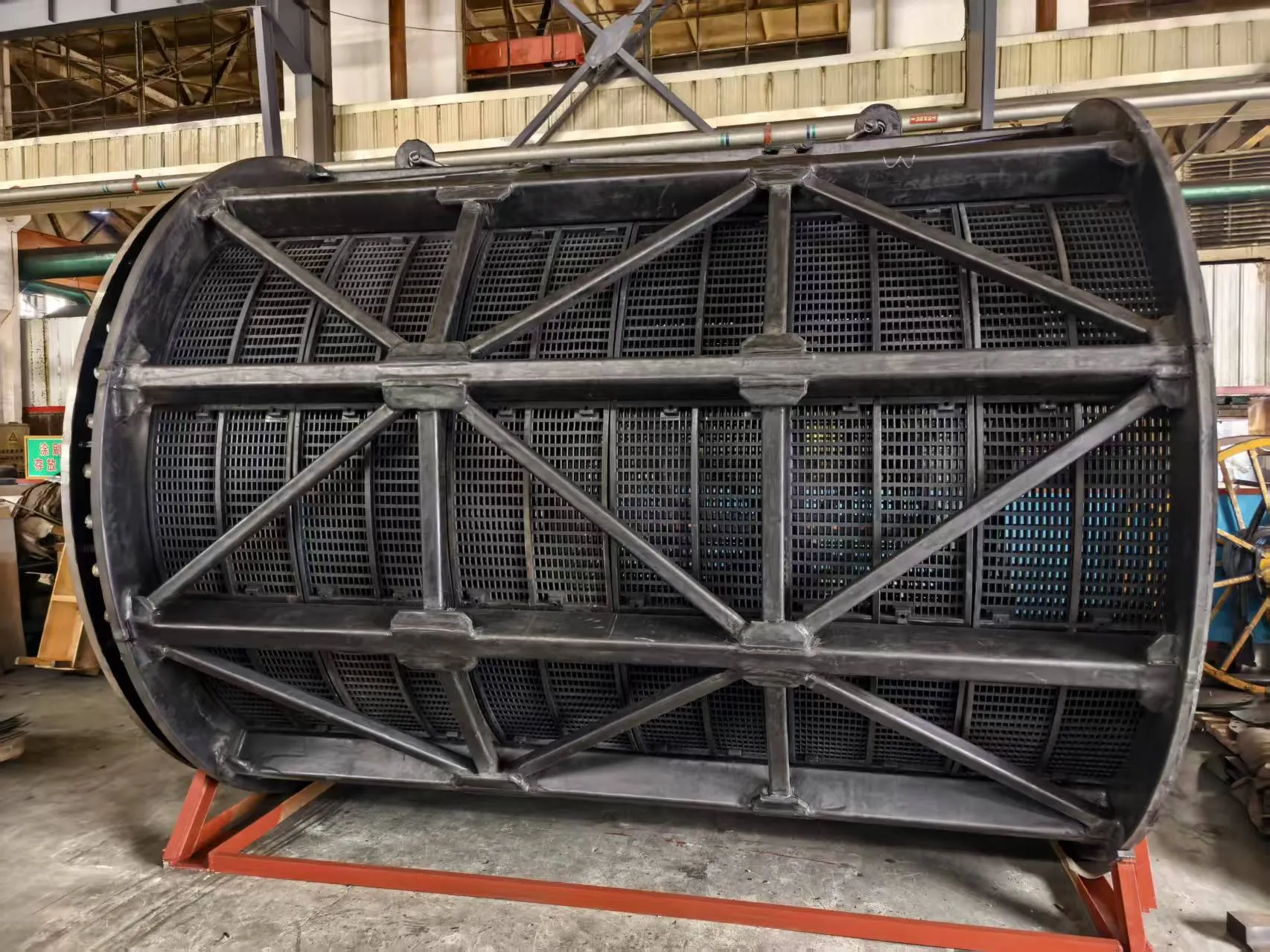

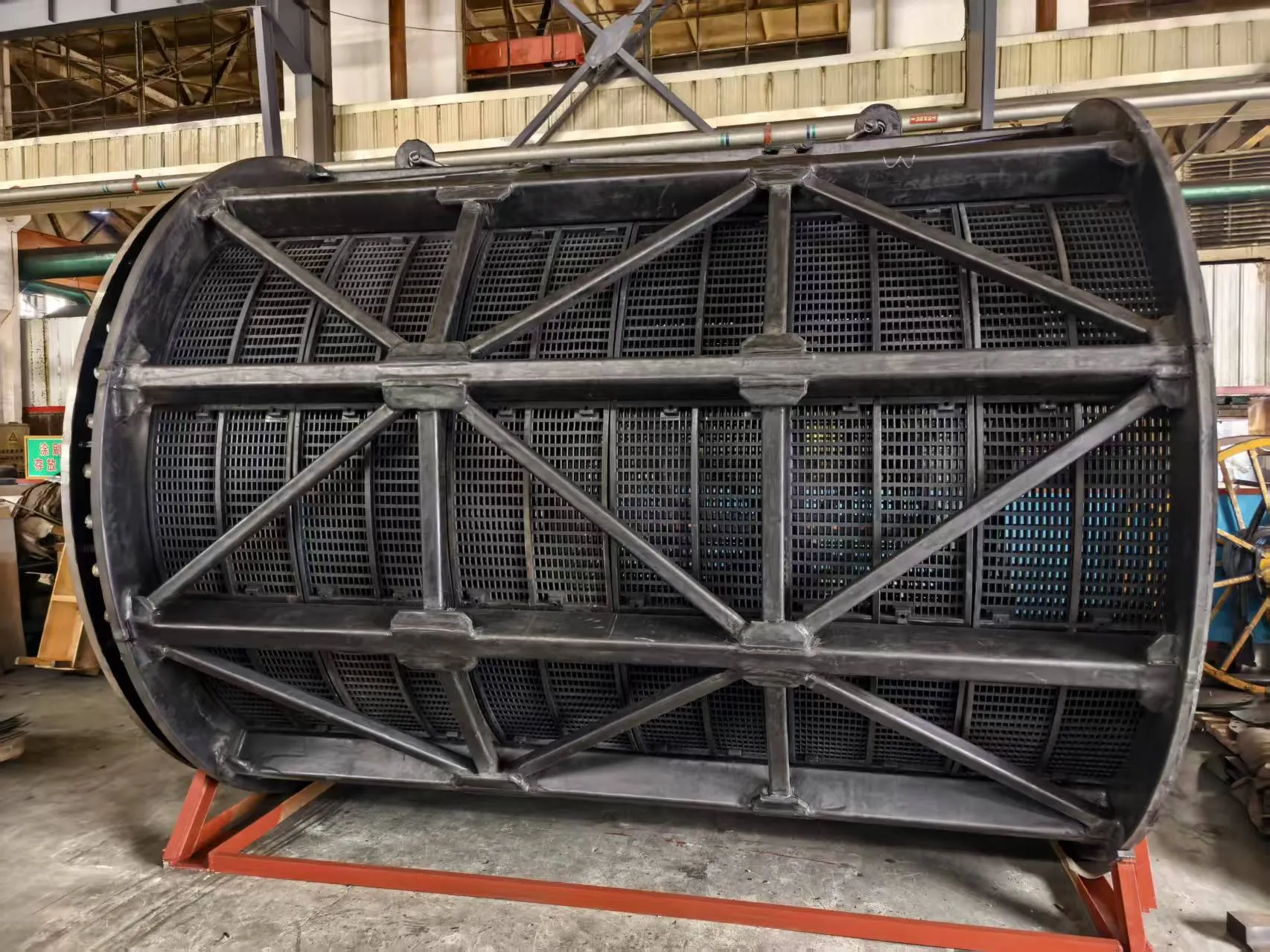

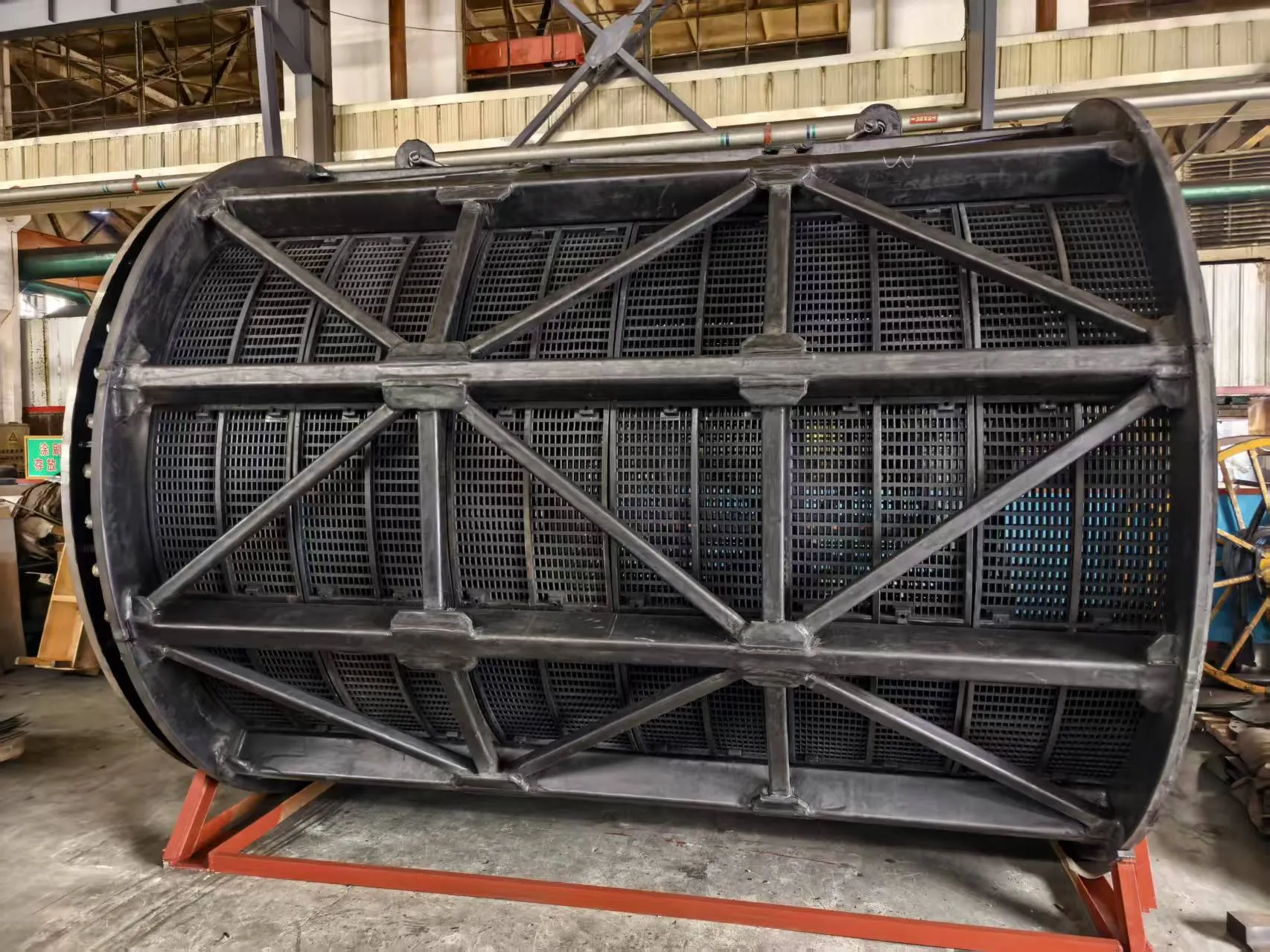

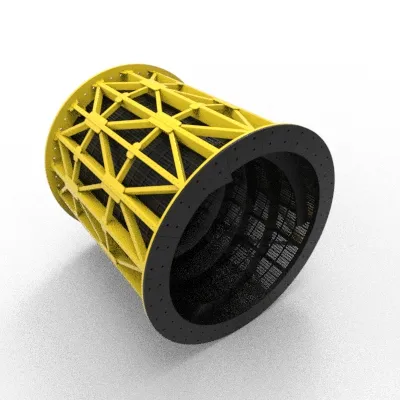

- Structure: It usually consists of a cylindrical drum with screen holes of specific diameters, a drive device including a motor and reducer, a frame for support, and sometimes internal lifting plates or spiral guide plates.

- Working Principle: The geared motor rotates the drum. When the materials discharged from the mill enter the drum, due to the drum's tilt and rotation, the materials on the screen surface are overturned and rolled. Fine materials smaller than the screen holes pass through the holes and are discharged as qualified products from the bottom of the drum's rear end. Coarse materials larger than the screen holes are retained in the drum and are conveyed back to the mill's feed end for regrinding by the action of lifting plates or spiral guide plates.

- Functions and Advantages

- Controlling Particle Size: It is the core function. It effectively separates materials into qualified fine particles and unqualified coarse particles, controlling the product's particle size.

- Preventing Overgrinding: By promptly screening out qualified fine particles, it avoids their repeated and ineffective grinding in the mill, reducing energy waste and the adverse effects of overgrinding.

- Improving Grinding Efficiency: The closed-loop system of screening and returning materials for regrinding significantly enhances the mill's overall efficiency, making the grinding media in the mill act mainly on the coarse particles that need further crushing.

- Protecting Downstream Equipment: It prevents large uncrushed materials or grinding media fragments from entering downstream equipment such as pumps, pipes, and flotation machines, avoiding blockages and damage.

- Applications

- Mining Industry: It is widely used in ore grinding and classification processes to improve the efficiency of mineral processing and the quality of concentrates.

- Cement Industry: In the cement production process, it is used to screen and classify cement raw materials and finished products to ensure the quality of cement.

- Chemical Industry: It is used for the screening and classification of chemical raw materials and products, helping to improve production efficiency and product quality.