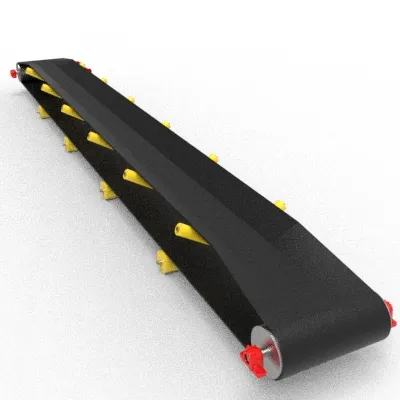

Fabric Rubber Conveyor Belts - Cost - Effective and Reliable Material Handling Solution

Short Description:

Explore the construction, performance characteristics, and applications of fabric rubber conveyor belts. Discover how their fabric - ply and rubber - layer design make them suitable for various industries, offering flexibility, load - bearing capacity, and abrasion resistance.

Content Details

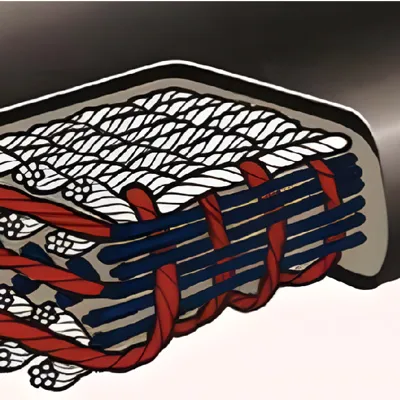

- Construction

- Fabric Plies

- Fabric rubber conveyor belts are built with multiple plies of fabric. Commonly used fabrics include nylon, polyester, and cotton. Nylon plies offer high tensile strength, making the belt suitable for heavy - duty applications where large amounts of material need to be transported over long distances. Polyester plies, on the other hand, provide good dimensional stability and are resistant to stretching, which is crucial for maintaining the accuracy of the conveyor system. Cotton plies are more budget - friendly and are often used in less demanding applications.

- Rubber Layers

- The fabric plies are bonded together and covered with rubber layers. The top cover rubber, which comes into contact with the conveyed materials, is formulated to resist abrasion, cutting, and impact. It can be made of different rubber compounds such as natural rubber, synthetic rubber (like SBR - Styrene - Butadiene Rubber), or a blend of both. The bottom cover rubber is designed to withstand the wear and tear caused by the conveyor rollers and idlers. It needs to have good adhesion to the fabric plies and sufficient flexibility to bend around the rollers smoothly.

- Fabric Plies

- Performance Characteristics

- Flexibility

- Due to the fabric construction, these belts are highly flexible. This allows them to conform to the shape of the conveyor rollers and pulleys, reducing the risk of damage to the belt and ensuring smooth operation. The flexibility also enables the use of the belts in conveyor systems with complex layouts, including those with curves and bends.

- Load - Bearing Capacity

- The number and type of fabric plies determine the load - bearing capacity of the belt. Belts with more plies or stronger fabric materials can carry heavier loads. For example, in a mining operation where large quantities of ore need to be transported, a fabric rubber conveyor belt with multiple high - strength nylon plies would be used to handle the heavy load.

- Abrasion Resistance

- The rubber cover layers, especially the top cover, are engineered to have excellent abrasion resistance. This is vital as the belt constantly rubs against the conveyed materials, which may be rough or sharp. The abrasion - resistant rubber helps to extend the belt's service life, reducing the frequency of belt replacements and minimizing downtime in the production process.

- Cost - Effectiveness

- Fabric rubber conveyor belts offer a cost - effective solution for many material handling applications. Compared to some other types of conveyor belts, such as steel cord conveyor belts which are more expensive, fabric rubber belts can provide sufficient performance at a lower cost, especially for applications where the load requirements are not extremely high.

- Flexibility

- Applications

- Mining Industry

- In mines, fabric rubber conveyor belts are used to transport ores, coal, and other mined materials from the extraction site to the processing plant. The belts' high load - bearing capacity and abrasion resistance make them suitable for handling large volumes of rough and heavy materials.

- Agriculture

- In agricultural settings, these belts are used to convey grains, seeds, and animal feed. Their flexibility allows for easy installation in various agricultural facilities, such as granaries and feed mills. The belts can also be designed to be food - grade compliant, ensuring the safety of the conveyed agricultural products.

- Manufacturing Industry

In manufacturing plants, fabric rubber conveyor belts are used to transport raw materials, semi - finished products, and finished goods. For example, in a food processing factory, the belts can be used to move products along the production line, while in a factory producing building materials, they can transport components from one workstation to another.

- Mining Industry