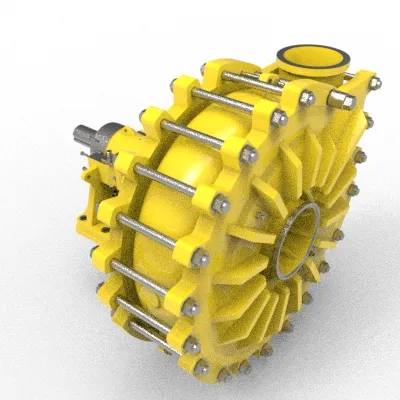

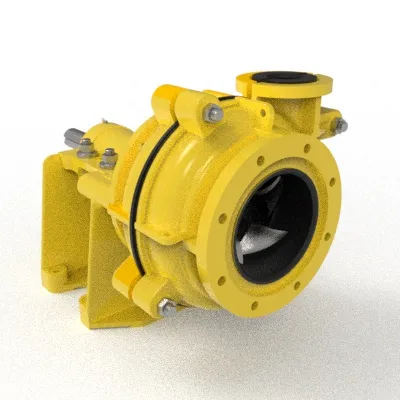

Bearing Components To Replace Warman Pumps

Short Description:

Our replacement bearing components for Warman pumps are engineered to the highes

- 1: 1

Content Details

Our replacement bearing components for Warman pumps are engineered to the highest standards, providing a seamless fit and optimal performance.

- High-Quality Materials

- Inner and Outer Rings: Manufactured from premium-grade bearing steel, such as GCr15, which offers high hardness, excellent wear resistance and good fatigue resistance, ensuring the bearing can withstand high loads and long-term operation.

- Rolling Elements: The rolling elements are made of high-quality chrome steel or ceramic materials. Chrome steel rolling elements have high strength and hardness, while ceramic rolling elements offer low density, high hardness, good corrosion resistance and low friction, which can reduce energy consumption and improve the efficiency of the pump.

- Cages: The cages are typically made of high-strength brass or engineering plastics. Brass cages have good wear resistance and heat dissipation performance, while engineering plastic cages have the advantages of light weight, low friction and good self-lubrication, which can effectively protect the rolling elements and improve the stability of the bearing operation.

- Advanced Design

- Optimal Clearance Design: The bearing clearance is precisely designed according to the operating conditions of Warman pumps. The appropriate radial and axial clearances are set to ensure that the bearing has good rotational accuracy and load-carrying capacity during operation, while reducing vibration and noise.

- Sealing Design: The bearing components are equipped with high-performance seals, such as rubber seals or labyrinth seals. Rubber seals have good sealing performance and can effectively prevent dust, water and slurry from entering the bearing, while labyrinth seals can form a multi-stage sealing structure through a complex channel design, improving the sealing effect and service life of the bearing.

- Excellent Performance

- High Load Capacity: Our bearing components can bear high radial and axial loads, adapting to the high-pressure and high-load working conditions of Warman pumps. Whether it is transporting high-concentration slurry or working under high-pressure conditions, the bearings can operate stably and reliably.

- Low Friction and Low Noise: Through the optimization of the surface finish of the bearing raceways and the selection of high-quality lubricants, the friction coefficient of the bearings is reduced, resulting in lower energy consumption and noise during operation. This not only improves the working environment but also reduces the load on the pump motor.

- Long Service Life: Thanks to the use of high-quality materials and advanced manufacturing processes, our bearing components have excellent wear resistance and fatigue resistance, which can significantly prolong the service life of Warman pumps and reduce maintenance costs and downtime.