TKM/MR - replaces the Warman M pump

Short Description:

Discover how TKM/MR outshines Warman M pump. Learn about its advanced design, higher efficiency, better wear resistance and lower maintenance in this comprehensive guide.

Content Details

The TKM/MR pump is a high-performance alternative designed to replace the Warman M pump, bringing a series of advantages and improvements.

- Design and Structure

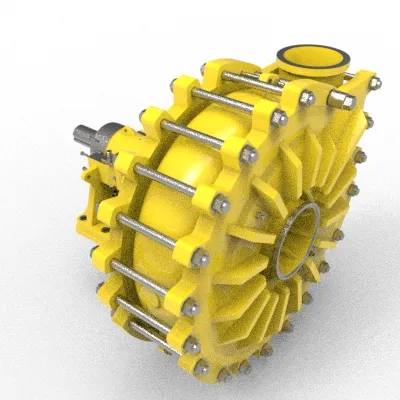

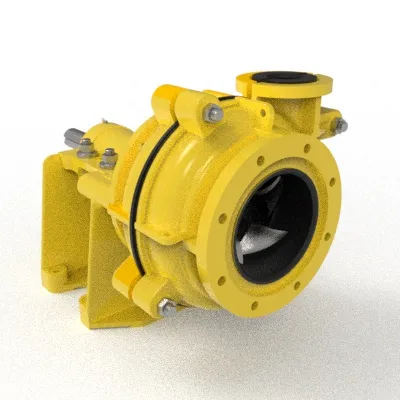

- Casing Design: The TKM/MR pump adopts a robust double-casing structure. The outer casing is made of high-strength ductile iron, providing excellent mechanical strength and stability to withstand high-pressure and high-abrasion working conditions. The inner casing is lined with wear-resistant and corrosion-resistant materials like high-chrome alloy or special rubber, effectively resisting the erosion of abrasive slurries and prolonging the service life of the pump.

- Impeller Design: Its impeller is a large-diameter, low-speed and high-efficiency design, which is manufactured from advanced abrasion-resistant alloys. The impeller has an optimized vane shape and angle, which can improve the hydraulic efficiency of the pump, reduce energy consumption, and enable the pump to handle large particle slurries smoothly.

- Shaft and Bearing System: The TKM/MR is equipped with a high-strength shaft and heavy-duty roller bearings. The shaft is made of high-quality alloy steel, which has high strength and torque transmission capacity. The heavy-duty roller bearings are housed in a low-profile fixed assembly, which can withstand high radial and axial loads, ensuring the stable operation of the pump and reducing vibration and noise.

- Performance Advantages

- Higher Efficiency: The TKM/MR pump has been optimized in hydraulic design, with a more reasonable flow passage and impeller structure, which can convert the energy of the motor into the kinetic energy of the slurry more effectively, improving the pumping efficiency. It can achieve higher flow rates and heads under the same power input compared to the Warman M pump.

- Better Wear Resistance: With the application of advanced wear-resistant materials and surface treatment processes, the TKM/MR pump shows excellent wear resistance in handling abrasive slurries. The wear-resistant alloy used in the impeller and casing can withstand the long-term scouring of large particles and high-concentration slurries, reducing the frequency of component replacement and maintenance costs.

- Lower Maintenance Requirements: The TKM/MR pump is designed for easy maintenance. It adopts a modular design, making it convenient to replace components such as the impeller and seal. The pump's structure is simple and clear, and the access to internal components is easy, which can significantly reduce maintenance time and labor costs.

- Functionality

- Wide Applicability: The TKM/MR pump is suitable for a variety of industrial applications, especially in mineral processing, metallurgy, coal and other industries. It can handle various types of slurries, including those with high solid content, large particles and high viscosity, meeting the needs of different production processes.

- Stable Operation: The pump is equipped with a stable drive system and control device, which can ensure stable operation under different working conditions. It has good adaptability to changes in slurry properties and flow rates, and can automatically adjust parameters to maintain optimal operation.